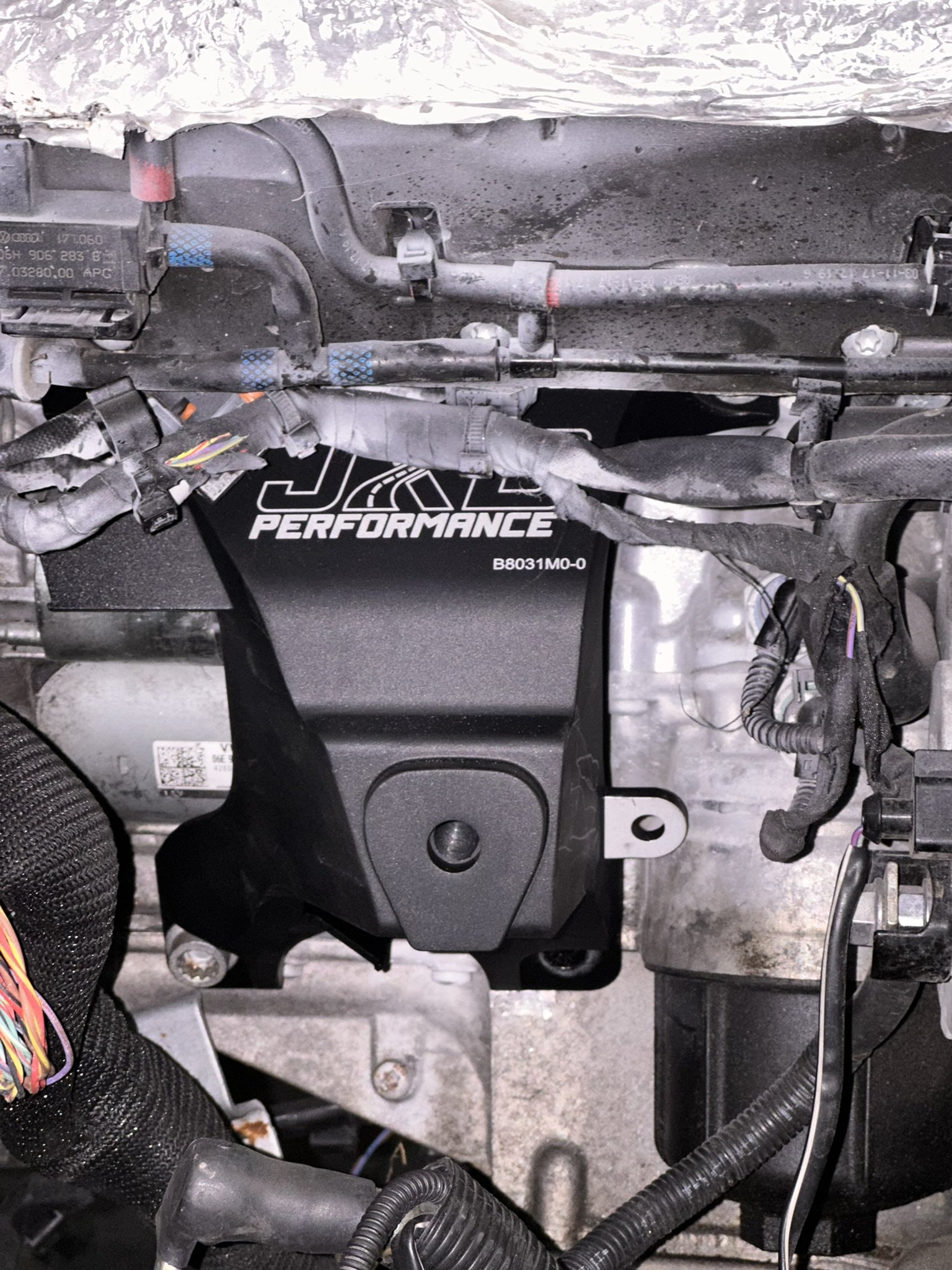

Audi B8/C7/D4 Spherical Front Lower Control Arm Shock Fork Bushings (B8007A0)

Set of 2. Core exchange available. See details below.

Set of 2. Core exchange available. See details below.

Set of 2. Core exchange available. See details below.

The front shock fork bushing is the lower attachment for the shock absorber to the forward lower control arm. In rubber form, it oscillates, flexes, and binds, resulting in less shock absorber efficiency, sluggish response, and higher lateral loads, which lead to earlier shock failure. The spherical upgrade eliminates these issues by providing the perfect attachment point for the shock.

These bushings are designed to be pressed into the factory positions in place of the OEM bushings. Typically this is done with an H-frame hydraulic press. Don’t want to deal with it? We’ll press them in for you. We’ll send you a set of factory arms completely assembled with our bushings. Just install them and send us back your original arms for the core refund. Select the core exchange option.

Note: JXB reserves the right to refuse at its sole discretion any returned core that is not in sellable condition. Conditions that may affect acceptance of core returns include but are limited to excessive surface rust or pitting, mechanical defects (scrapes, dents, stripped holes, etc), and integral ball joints with excessive wear. If you are unsure of the condition of your cores, please send detailed pictures before returning them.

We use only the highest quality motorsport-grade PTFE-lined bearings for best performance and lifespan. We use high strength 7075 aluminum for the bolt sleeves, and 6061 for the bearing cups. Bearings are interference-fit into the cups, so they won’t rattle. Both internal and external retaining rings ensure everything will always stay in place.

Please note that lifespan will vary based on the application and driving conditions. Spherical bearings do have moving parts, so they do wear. Our bearing kits are fully rebuildable. Please contact us for rebuild kits.

Rubber bushings act like little springs at each suspension pivot point. They allow suspension geometry to change under load, ruining your alignment and causing unwanted handling characteristics like steering wander, binding, camber, caster, and toe changes, and lack of steering and suspension feedback. Spherical bearings do not bind or flex under load, creating perfect suspension joints.

Spherical bearings are known to produce creaks and pops in the suspension as they age. Though we only use PTFE-lined motorsport grade bearings (the best and most durable you can get), we’ve found the PTFE liner is rarely sufficient to keep the bearing fully lubricated and free-moving over the course of its life. We’ve found after a year or two, some bearings will start to creak right as they start moving or when they switch from moving one direction to the next. As they start to wear they will also become looser over time, eventually making a very small gap between the ball and outer race. This gap can cause a noise similar to if you had a slightly loose bolt or ball joint. When these symptoms start to occur, relubricating them with a synthetic PTFE grease will quiet them down and smooth out their movements very nicely. We recommend doing this at least once per year or every 5 to 10 thousand miles as part of a regular maintenance routine. A thick layer of grease covering the exposed parts of the bearing will also act as a moisture and dust barrier, keeping as much crud out as possible. The more often you can clean and regrease, the more life you’ll get out of them. We’ve found with proper care you can get 20-40,000 miles out of a set of bearings.

With all this said, please understand that these bushings are designed around ultimate performance in motorsport settings. With anything high performance will come more maintenance, and these are no exception. Please consider whether you are willing to sign up for the maintenance before going the spherical route.

A few tips to get these pressed in correctly.

Use a hydraulic press. A typical screw-driven bushing installation tool will not have the strength to do it.

Lubricate the mating surfaces well before installation. This will reduce press forces by around 50% and greatly reduce the risk of damage to the control arm or bushing.

Measure the diameters of the hole and the bushing before installing. OEM (and especially aftermarket) control arm hole diameters can vary pretty wildly. Interference of .002-.007” is ideal. Looser and they may knock around. Tighter and they may require extreme press forces and will be very likely to gall the mating surfaces during installation. If the interference is too high, you can lightly sand/file/ream the hole out until it’s in the correct range.

For easier installation, heat the control arms and cool the bushings. This will reduce the interference thereby reducing the press forces needed.

Make sure the control arm hole is clear of burrs, debris, and any abnormalities.

Usually one side of the control arm hole is tapered. Press the bushing in from that side for easier, safer install.

Wear eye protection and be safe. Press forces often exceed 5 tons. If/when something breaks or your assembly contraption slips, it can be extremely dangerous.

We cannot be responsible for damage or injury due to installation mishaps, though we will work with you to subsidize replacement parts. Be careful! If in doubt about your abilities to do it correctly, use our core exchange program or contact us and send us your control arms and we’ll do the installation for you.

Fits the following vehicles:

Audi B8 A4/S4/RS4/A5/S5/RS5

Audi B8 Q5/SQ5

Audi C7 A6/S6/RS6/A7/S7/RS7

Audi D4 A8/A8L/S8