Image 1 of 4

Image 1 of 4

Image 2 of 4

Image 2 of 4

Image 3 of 4

Image 3 of 4

Image 4 of 4

Image 4 of 4

Audi B6/7 A4/S4 with 6HP19 Auto Driveshaft Center Support Bearing Carrier Upgrade (B6004A0)

IN STOCK. SHIPS SAME-DAY IF ORDERED BEFORE 12PM CST M-F.

Reduces drivetrain slop

Restores and maintains driveshaft alignment

Installs without having to remove or disassemble the driveshaft

IN STOCK. SHIPS SAME-DAY IF ORDERED BEFORE 12PM CST M-F.

Reduces drivetrain slop

Restores and maintains driveshaft alignment

Installs without having to remove or disassemble the driveshaft

IN STOCK. SHIPS SAME-DAY IF ORDERED BEFORE 12PM CST M-F.

Reduces drivetrain slop

Restores and maintains driveshaft alignment

Installs without having to remove or disassemble the driveshaft

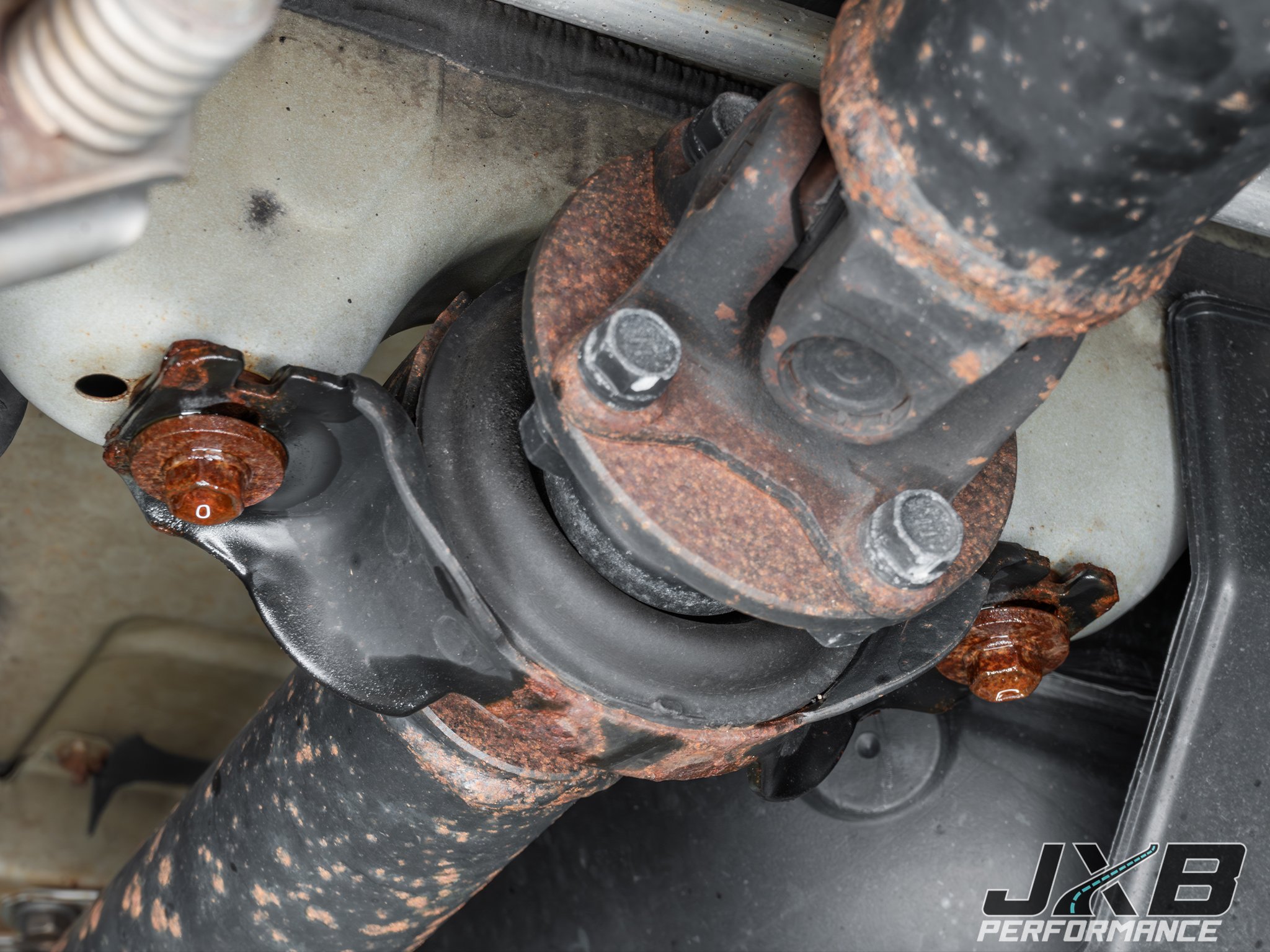

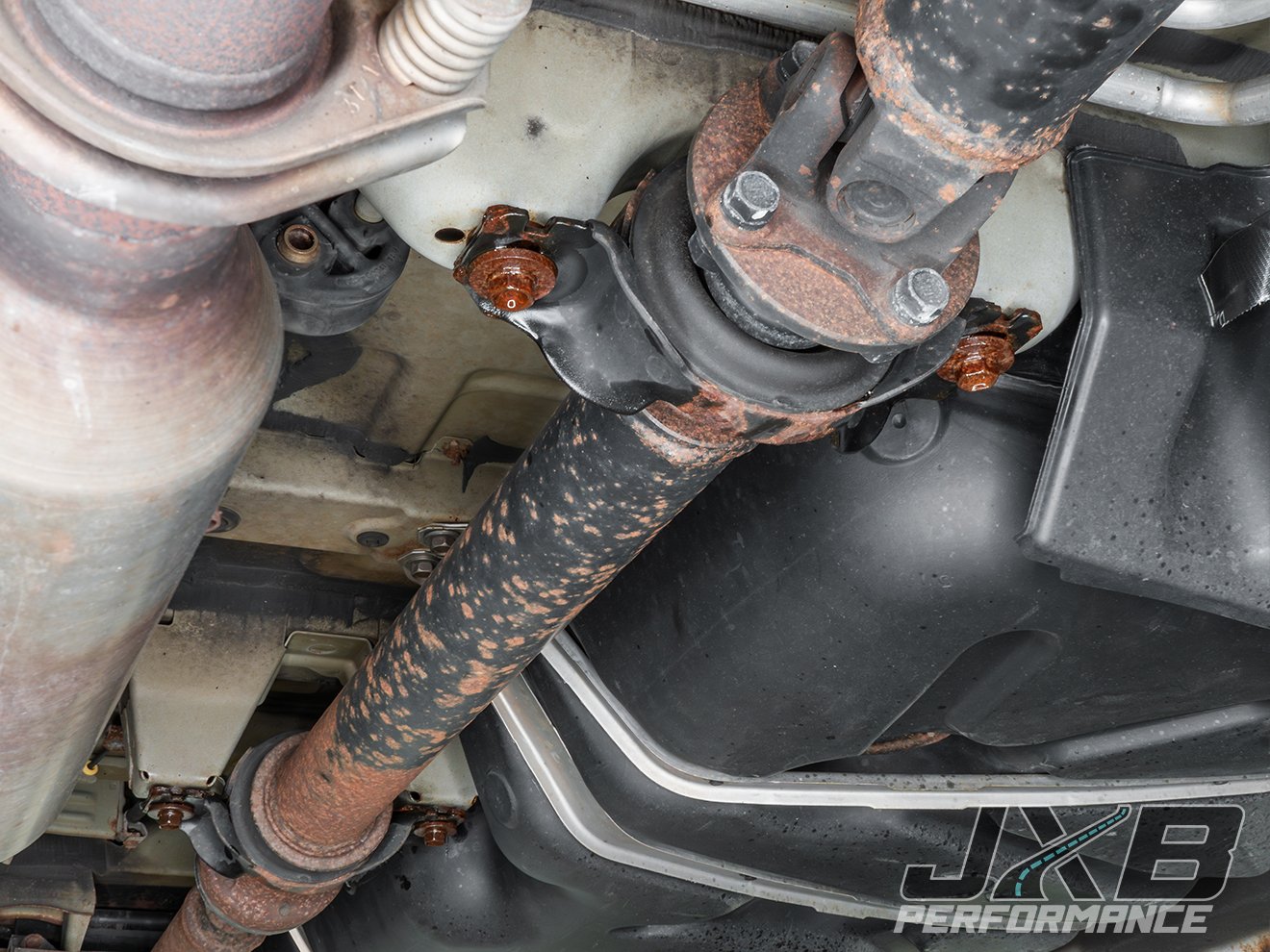

The stock center support bearing carrier holds the driveshaft in place with a layer of thin rubber. While that’s great for making sure no NVH makes it to the cabin, it doesn’t keep the bearing centered well under load, allows the bearing to sag and ruin driveshaft alignment over time, and creates slop in the driveline during shifts and throttle application.

Over time the OEM bushing becomes brittle, eventually dry rotting and cracking. Even on the best-kept cars, the stock bushing can start to form cracks in as little as 5-10 years.

When the bushing wears and sags, it changes the alignment of the driveshaft, putting more stress on the joints. During rapid loading of the driveshaft (launches, shifts, and quick application of the throttle), the bearing is allowed to travel off-center, introducing slack in the driveline, which results in laggy and unpredictable driveline response.

Our upgraded driveshaft carriers keep the driveshaft firmly in place at all times. The more solid bushings ensure the bearing cannot move from center, maintaining torque delivery and driveshaft alignment at all times, resulting in more direct driveline response under all conditions.

Benefits as described by our customers include:

More direct throttle response

Firmer, more direct shifts

More instantaneous launches

Reduction in vibration due to driveshaft misalignment and/or rubber deterioration

Smoother low-speed on/off throttle behavior (1st gear in parking lots)

The videos below show how OEM driveshaft carriers react to driveshaft loads and the improvement with our carriers.

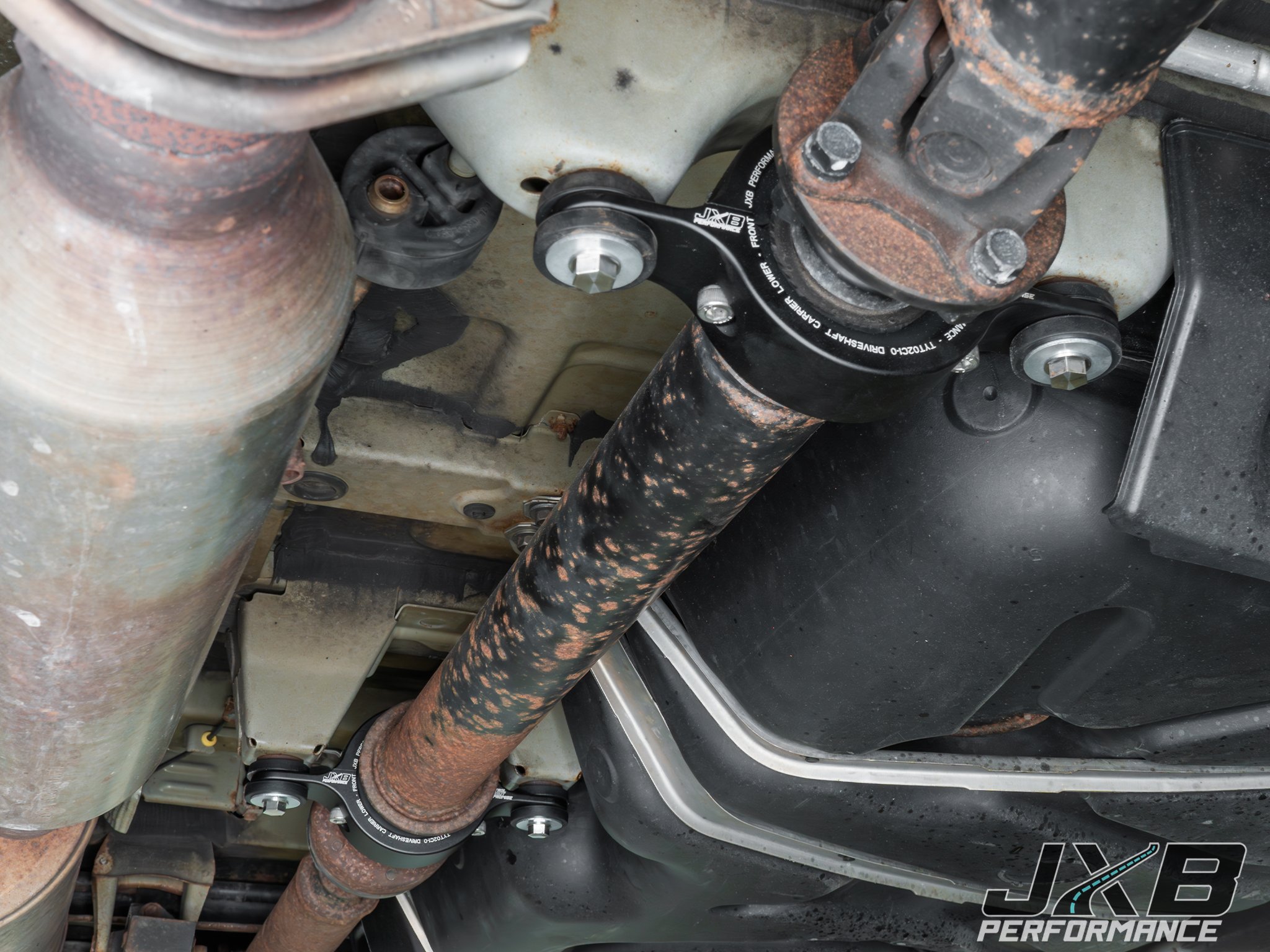

Installation doesn’t require removal of the driveshaft. The 2-part design clamps around the unserviceable OEM bearing. The old carrier must be removed, so a cutting tool is required.

The exact steps to access the carrier will vary slightly by model, but the removal and installation of the new carrier are the same. The basic steps are:

Remove any braces or splash shields preventing exhaust and heat shield removal

Remove or lower exhaust in area of center support bearing if needed for access

Remove heat shielding covering center support bearing

Cut off OEM carrier and remove rubber support material with razorblade, leaving base layer of molded-on

rubber intact on the bearing

Clamp new carrier around OEM bearing

B6/7 A4/S4 with 6HP19 transmission (6-speed automatic)

Street and Track refer to the durometer (stiffness) of the bushings. Track are roughly twice the durometer of the street bushings. Both track and street are many times stiffer than stock and will hold up to whatever abuse are thrown at them, but the street bushings are better at soaking up drivetrain noise and vibration. Usually both street and track are completely silent and vibration-free, but in cases where there is an underlying drivetrain issue causing the driveshaft to vibrate badly, the track bushings may not be able to soak it all up, where the street bushings can.

We generally recommend street bushings for any car that's not purpose-built for track or overland use, since the street bushings have a much lower chance of transmitting drivetrain NVH to the cabin at high speeds or under heavy throttle loads.

If you’re not sure which to go with, the “Give me Both!” option will give you a full set of each of the street and track bushings. You can use all street, all track, or even mix and match them to find the perfect balance of performance and NVH-absorption.