Toyota Sienna 2nd/3rd Gen Driveshaft Center Support Bearing Carrier Upgrade (TYT02A0/1)

IN STOCK. SHIPS SAME DAY IF ORDERED BY 12PM CST.

Optional spacer kit for cars equipped with 3.5” JOR lift corrects driveshaft angles

Reduces drivetrain slop

Restores and maintains driveshaft alignment

Installs without having to remove or disassemble the driveshaft

IN STOCK. SHIPS SAME DAY IF ORDERED BY 12PM CST.

Optional spacer kit for cars equipped with 3.5” JOR lift corrects driveshaft angles

Reduces drivetrain slop

Restores and maintains driveshaft alignment

Installs without having to remove or disassemble the driveshaft

IN STOCK. SHIPS SAME DAY IF ORDERED BY 12PM CST.

Optional spacer kit for cars equipped with 3.5” JOR lift corrects driveshaft angles

Reduces drivetrain slop

Restores and maintains driveshaft alignment

Installs without having to remove or disassemble the driveshaft

The Driveshaft Carriers

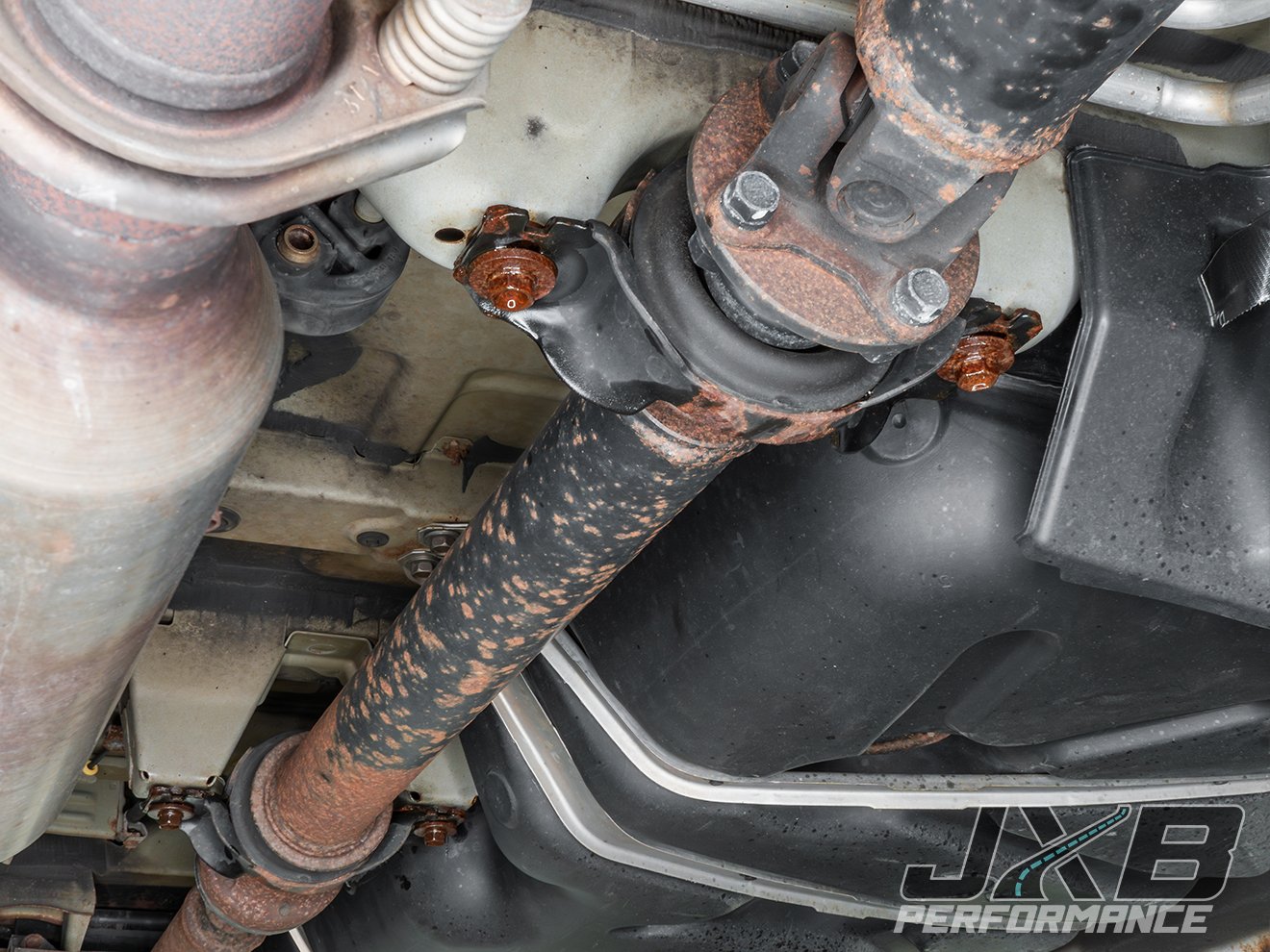

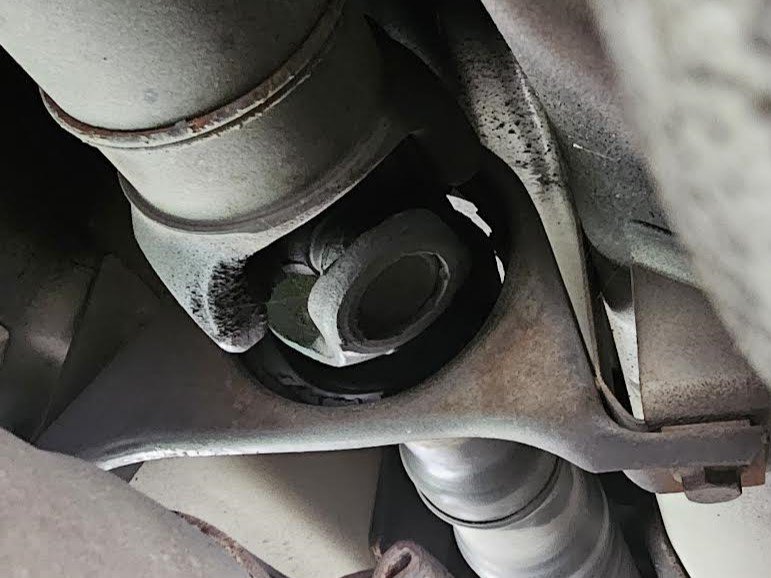

The stock center support bearing carrier holds the driveshaft in place with a layer of thin rubber. While that’s great for making sure no NVH makes it to the cabin, it doesn’t keep the bearing centered well under load, allows the bearing to sag and ruin driveshaft alignment over time, and creates slop in the driveline during shifts and throttle application.

Over time the OEM bushing sags, ruining driveshaft alignment and putting more stress on the joints.

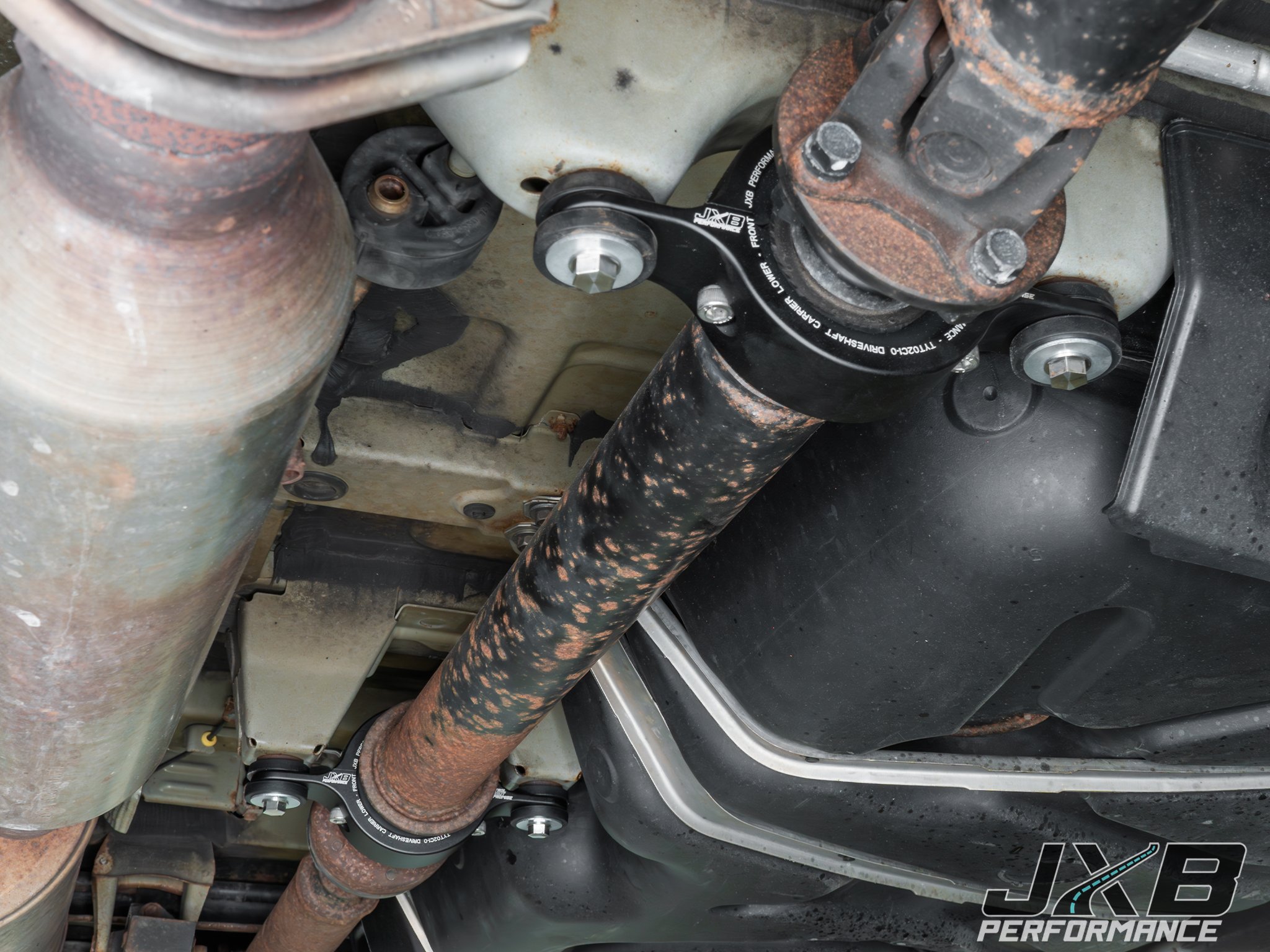

Our upgraded driveshaft carriers keep the driveshaft firmly in place at all times. The more solid bushings ensure the bearing cannot move from center, maintaining torque delivery and driveshaft alignment at all times, resulting in more direct driveline response under all conditions.

Benefits as described by our customers include:

More direct throttle response

Firmer, more direct shifts

More instantaneous launches

Reduction in vibration due to driveshaft misalignment and/or rubber deterioration

Smoother low-speed on/off throttle behavior (1st gear in parking lots)

The Spacer Kit for 3.5” JOR Lifted Vans

In the process of designing these carrier upgrades, we found that the most popular lift kit for the platform (3.5" JOR) has a drastic effect on the angles of the rear section of the driveshaft. We reached out to the manufacturer to ask if they offered a center support bearing spacer kit, and were told people didn't have any vibration or other issues after installing, so it wasn't necessary. Doing some calculations after measuring some things on our stock-height test vehicle, we found that the 3" drop of the diff relative to the body would result in a 6° change in angle of the rear portion of the driveshaft. This makes the misalignment at the rear center support bearing's u-joint go from 1.5° (stock) to 7.5°, which is a huge misalignment for a u-joint to handle. From experience on other lifted vehicles, this kind of misalignment generally does create vibration in the driveline, and the vibration coupled with the larger pinion angle at the connection to the rear differential wreaks havoc on the u-joints and support rubber while accelerating wear on the differential pinion bearings.

Our next step was to get a 3.5" JOR lifted vehicle in-house to see what was really going on. Upon our first test drive before adding any of our parts, we immediately noticed driveline vibrations under low-speed high-load scenarios like WOT in 1st/2nd gear. This is the most common sign of a driveshaft misalignment, since u-joints do not spin smoothly when off by more than a couple degrees. We measured driveshaft angles and found a 7.9° difference between the rear two sections, even more than we had calculated. Angles of the 3 sections from front to back (NU/ND=nose up/down) were 3.0° NU, 0.9° ND, and 7.0° NU. For reference our stock test fit van was 0.4° NU, 0.2° NU, and 1.7° NU. We went to work realigning the drivehsaft with various spacer sizes, and were able to completely eliminate all load-based vibrations. Go figure, the configuration we settled on that eliminated all vibrations turned out to be within Toyota's spec shown in the factory service manual! The final angles were 1.2° NU, 1.2° NU, and 3.0° NU. To put them all in one place:

- Stock - 0.4° NU, 0.2° NU, and 1.7° NU

- Lifted - 3.0° NU, 0.9° ND, and 7.0° NU

- Corrected - 1.2° NU, 1.2° NU, and 3.0° NU

These spacers will prolong the lifespan of the rear two u-joints and the differential pinion bearings, while eliminating driveshaft vibrations due to severely misaligned u-joints. We recommend them for any van lifted with the 3.5” JOR kit.

The video below shows a comparison of how much the OEM carrier gives under load and the improvement with the JXB carrier.

Installation doesn’t require removal of the driveshaft. The 2-part design clamps around the OEM bearing. The old carrier must be removed, so a cutting tool is required.

Installation with no CSB Spacers

Installation with CSB Spacer Kit for 3.5” JOR Lifted Vehicles

The exact steps to access the carrier will vary slightly by model, but the removal and installation of the new carriers are the same. The basic steps are:

Remove any braces or splash shields preventing exhaust and heat shield removal

Remove or lower exhaust in area of center support bearing

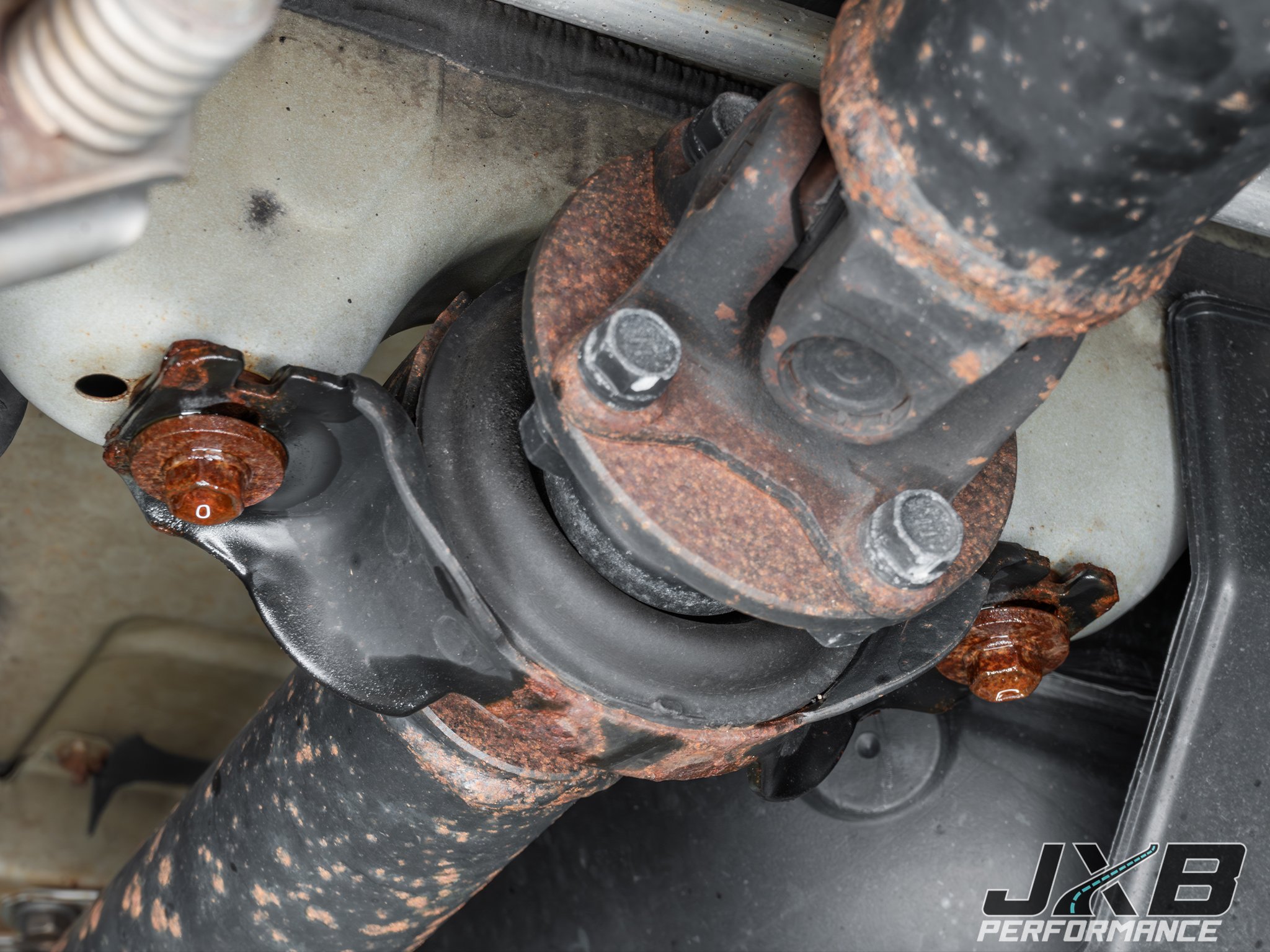

Remove heat shielding covering center support bearing

Cut off OEM carrier and remove rubber support material with razorblade, leaving base layer of rubber intact on the bearing

Clamp new carrier around OEM bearing

2nd/3rd gen (XL20/XL30/XL40) Toyota Sienna (2004-2020) (AWD Only)

Also fits:

1st/2nd/3rd gen (XU20/XU40/XU50) Toyota Highlander (2001-2019) (AWD Only)

1st/2nd/3rd/4th gen (XU10/XU30/AL10/AL20) Lexus RX 300/350 (1999-2022) (AWD Only)

Street and Track refer to the durometer (stiffness) of the bushings. Track are roughly twice the durometer of the street bushings. Both track and street are many times stiffer than stock and will hold up to whatever abuse are thrown at them, but the street bushings are better at soaking up drivetrain noise and vibration. Usually both street and track are completely silent and vibration-free, but in cases where there is an underlying drivetrain issue causing the driveshaft to vibrate badly, the track bushings may not be able to soak it all up, where the street bushings can.

We generally recommend street bushings for any car that's not purpose-built for track or overland use, since the street bushings have a much lower chance of transmitting drivetrain NVH to the cabin at high speeds or under heavy throttle loads.

If you’re not sure which to go with, the “Give me Both!” option will give you a full set of each of the street and track bushings. You can use all street, all track, or even mix and match them to find the perfect balance of performance and NVH-absorption.

Full Assemblies

Without 3.5” JOR Lift Spacer Option

Street - TYT02A0-S

Track - TYT02A0-T

Both - TYT02A0-B

With 3.5” JOR Lift Spacer Option

Street - TYT02A1-S

Track - TYT02A1-T

Both - TYT02A1-B

Spare Bushing Sets

Street - 2x BSH09A0

Track - 2x BSH09A1

Spare Hardware Set

Without 3.5” JOR Lift Spacer Option

2x SHS10A1

With 3.5” JOR Lift Spacer Option

SHS11A1